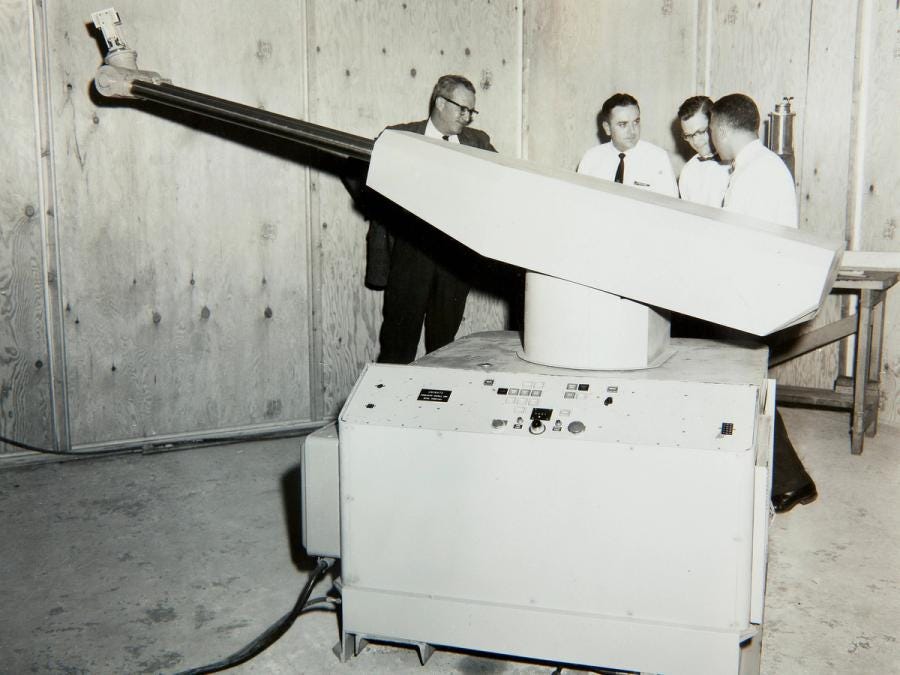

Industrial robots are amazing, and they have been around for a long time. The first industrial robot was sold in 1961. This workhorse was used on a General Motors assembly line, lifting die castings to automate welding processes. This robot was called Unimate.

We have come a long way since 1961, although I am still very impressed after reading about it. This machine is bigger than you think and still accurate to within 1mm.

This robot had 6 joints, 3 in the wrist and 3 in the arm, for a total of 6 degrees of freedom, costing around $263,065 in today’s money. Capable of moving heavy die castings in an automotive factory, this was worth the cost. Robots today will cost you between $25,000 and $400,000. Factors such as payload, work envelope, speed, precision, and joint count will ultimately determine the cost of the robot. The payload of industrial robots can be as small as 100g or as large as 2,300kg, as in the case of the M-2000iA/2300

As you continue to add joints to the robot, the potential orientations of the end effector (tip of the robot arm) become infinite. In such a case, the robot arm is very well actuated and can do almost any task if programmed correctly.

When paired with sufficiently advanced software, robot arms become immensely useful, expanding their potential for work as the software improves. The advent of AI imbues older technology with the capacity to do more than the dull repetitive work that is traditionally saved for programmed robot arms.

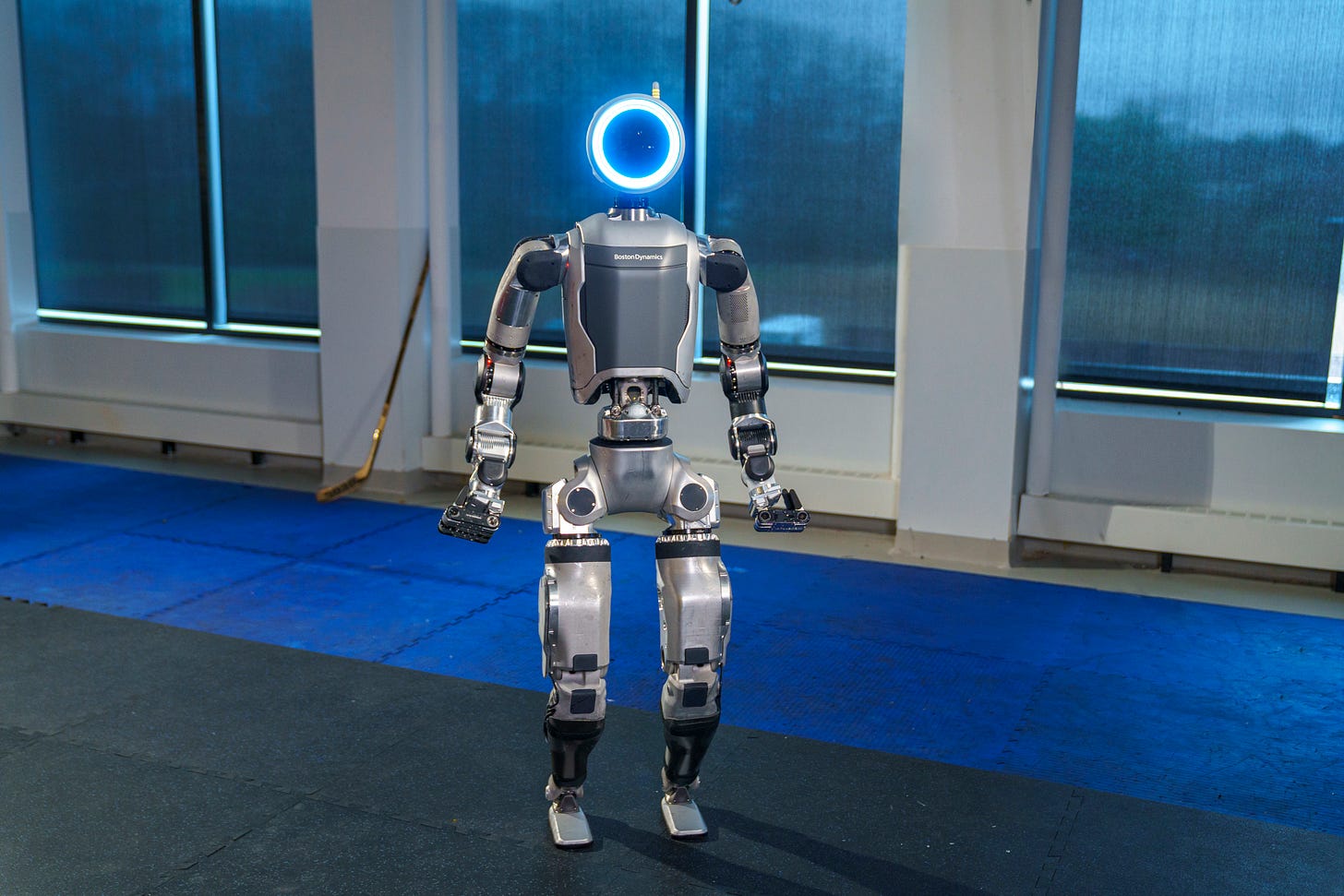

Software is the key to robot utility. New emerging techniques that allow robots to behave autonomously in ways that were previously impossible are on track to transform the industry. There is an ongoing debate as to whether the human form is optimal for performing useful tasks in the world. As you can see, the robot above is very complicated. It has at least 40 degrees of freedom and is very expensive to manufacture and assemble.

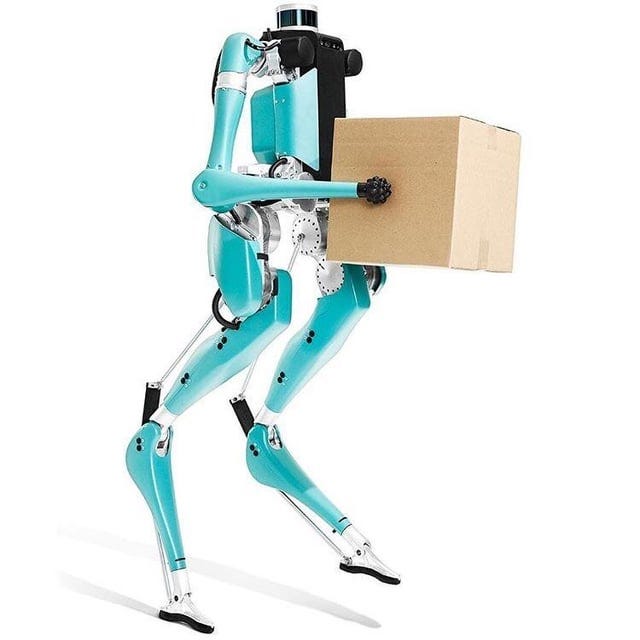

Other companies are changing the form factor, and it is likely that there will be many useful variations in the years to come.

I am inspired by products such as this, and I want to learn how to build systems capable of doing useful things. Thanks to 3D printers, hobbyists can now build rough robots themselves with inexpensive parts made from cheap materials with sub-millimeter precision. Teaching yourself has never been easier. Most of the potential of robotics lies in software, therefore there is a lot to learn from a simple homemade platform. This is why I am building my own robot arm.

There are many issues that you have to face when designing your own robot arm with 3D printed parts. Most notably, backlash. Backlash is the slop between moving components that causes imprecision in the movement of your robot arm.

Precision gearboxes are expensive, and in my case, getting a premade actuator for one of the joints would cost more than all of the other hardware combined. Eventually, I settled on a design that could be mostly 3D printed, limiting the number of moving parts and keeping backlash low while ensuring smooth motion. I eventually decided on a worm drive actuator. There are quite a few compromises to this design, such as low efficiency, potential for wear over time, and that it is not back-drivable. But it is quiet, cheap, and very easy to assemble and replace parts for.

When properly lubricated, this gearbox is quite powerful with a 40:1 reduction. The robot is still in the assembly and adjustment phase, so we will see how it performs. I will eventually do a post just on actuators. They are very interesting, and you can achieve some amazing precision with very simple components.

Eventually, I would love to modify my robot so that it can weld, draw, or be trained in a simulation to do more complicated tasks with perception. But for now, I need to build the thing and figure out how to make it move. There is a lot to learn, and I will continue to post updates talking about the topics that I am actively struggling to implement into the design. The ultimate goal for this robot is to make it generally useful for under $500. This is a very hard software and hardware challenge, as most robots the same size cost around $5,000. But this is what makes it worthwhile. As with any creative pursuit, constraints often enhance innovation. I will make posts about more topics like this in greater detail in days to come. Thanks for reading!

wonderful to read your blog Aaron!!!! 🥳🥳